Stage 2 of the Australian Defence Force’s accommodation upgrade to their Single Living Environment and Accommodation Precinct (LEAP) in Darwin saw the construction of 918 new apartments. It was a highly organised development that had strict protocols and required innovative task management to accomplish the project.

Stage 2 of the Australian Defence Force’s accommodation upgrade to their Single Living Environment and Accommodation Precinct (LEAP) in Darwin saw the construction of 918 new apartments. It was a highly organised development that had strict protocols and required innovative task management to accomplish the project.

This upgrade will improve and better integrate the living standards and communities where single defence personnel reside. The project is being managed by the Plenary Group, recognised as international specialists in providing whole community concepts, with Woods Bagot as the architect.

G.James Role

G.James Glass and Aluminium’s Darwin office successfully negotiated the contract to supply and fit glazed windows, door frames, security doors and louvres to the various planned concepts in two locations – Larrakeyah (in the city) and Robertson (rural). Each site had individual acoustic, thermal (energy efficiency), wind loading, water penetration and bushfire requirements which formed part of the specification. To ensure compliance, G.James undertook product modifications, the development of new systems and conducted testing for the intended suites. The contract is to be achieved in two phases of supply and installation that span over 1 ½ years.

G.James is organised to take on projects of this scope. Divisions including business support services and transport are combined with a large workforce and the latest technology to fulfil the resource requirements of larger ventures. For the Darwin project, initial discussions internally located potential branches with facilities and personnel available. Once the project was awarded, managers designated the resources available to meet the commitments.

Design

Darwin comes with stringent water and wind pressure requirements. Product testing was needed for the new 472 Series door framing system and the 246 Series sliding door for Darwin’s conditions.

Energy efficiency was addressed using IGU’s. This also helped resolve the acoustics issue at the Robertson location, as there was a flight path located overhead.

BAL Rating

Bushfire ratings are addressed at the Robertson location due to the proximity to bushland in its rural setting. A Bushfire Attack Level (BAL) rating is given to an area or facade to determine the requirements of the materials used. Glass and gaskets are selected that comply with these conditions from the G.James BAL Manual.

The BAL ratings applied to G.James materials have been determined from AS3959 as “Deemed to satisfy” or the prescriptive method. The prerequisite for the physical properties of glazing materials in bushfire prone areas is to resist ember attack and radiant heat transfer. Your local branch or G.James representative can give you further information on BAL compliant products available.

Implementation

The work was divided up in accordance with the capabilities and current workloads of various branches. Some were accustomed to this volume of work, and others were introduced to it. The branches involved are outlined as follows, with a brief summary of the who they are, and a quote about what this project entailed for them:

Head Office

Initially, the Business Support Service division at G.James’ Head Office assisted the Darwin branch with project specific engineering, product design, contract administration and material / production coordination.

“This included a review of the products to create efficiencies in product manufacture and installation. Because of the distance that products were to travel by road, we also orchestrated the design of several specific packing crates.” – John Staunton (Manager of Business Support Service).

G.James’ Head Office is charged with the role of being the central point of direction for the branches with regards to technical advice, administrative services and major project logistics & coordination. This responsibility is assisted in the fact that the Head Office is in close proximity to the Group’s major manufacturing facilities at Eagle Farm.

Maroochydore Branch

Maroochydore supplied the entry door frame, highlights and sidelights made with the new 472 Series, as well as Crimsafe screens.

“For 12 months, the Darwin Defence Accomodation has been keeping our commercial and Crimsafe departments with a constant flow of work. The Emmegi CNC machine has been vital part of the processing for the doors required on this project” – Darren Mahoney (Branch Manager)

Bundaberg Branch

Bundaberg worked on 475 Series fixed louvre grill and top hung sliders, Crimsafe screens for the 246 Series sliding doors, and 475 Series hinged Doors.

“It has been amazing to see the various number of branches working together to have all items made, packaged and then transported to Darwin (without damage) ready for installation all within the tight time frames. “ – Damian Perry (Estimator)

KDC

KDC (or the Knock Down Components factory in Brisbane) cut and processed assembly kits for the 246 Series sliding doors.

“We have only had to replace two door frames due to transit damage which demonstrates our attention to detail and ability to supply component parts to the correct specification on time to allow for efficient project management ongoing.” Jason Claridge (Branch Manager)

KDC typically make standard glazing packages for nationwide distribution.

Riverview

Riverview provided framing for the 472 Series fixed glazing and hinged doors.

“Riverview are accustomed to national distribution, being the only manufacturers of double hung windows, so coordinating this project was not out of character. It did allow us to contribute our other skills and it was fantastic to be a part of such a combined effort.” – Ben Driessen (Branch Manager)

Along with Double Hung Windows, Riverview have a stock of unusual glass types and patterns that are invaluable to replacing period style glass.

Woodridge

Woodridge took care of the 048 Series fixed and awning windows.

“The scale of work for this job saw our manufacturing processes streamlined. It is good to know just how much work we are capable of doing.” – Garry Fulton (Branch Manager)

Woodridge produces almost all products made by G.James products (except double hung), and services the area from south of the Brisbane river to the top of the Gold Coast and out to Manly and Redland bay. They also make a lot of commercial products for Western Australia, and supply 048 series hopper windows to other branches and departments.

Glass Department

The Glass Department in Brisbane manufactured all the glass for the project.

“Our glass department is built to take mass orders of this size, so implementing it was not a problem. It is good to work on this scale of project, knowing we are contributing to such a large G.James effort. It is what makes G.James the company we are – we have the ability to take on this kind of work as we have the most sophisticated and modern technology available to us.” – Tony Evans (Operations Manager)

The sizeable glass operations produce many different types of glass – from sizing annealed, coated and tinted, to manufacture of laminated, toughened, printed, patterned as well as IGU’s.

Mechanical and Transport Division

Mechanical and transport departments provided transport for all the components to be brought to Brisbane for coordination and shipping to site.

“We coordinate this type of work all the time – the volume of this job was quite large, however, and meant strict management of delivery – the right products at the right time.” – John Erskine (Transport Manager)

Transport run a fleet of trucks up and down the East Coast of Australia (Sydney to Cairns) to service delivery of the full range of G.James products.

Darwin

Darwin – project coordination and implementation.

” We would never have been able to pull it off without the support of all the other branches that got involved and helped us make this job a reality. To everyone – thanks, it was greatly appreciated.” – Scott Harris (Branch Manager)

On Site

The products, when ready, were transported to Darwin, and fixers were sub contracted to carry out the vast workload at installation. Attention to detail was essential as all the glass for this project was site fitted because of additional fixings in the glazing pocket required to meet the high local wind loads.

Project status

The project is in its final stages, and is projected to be complete by the end of this year (2013). Coordinating our resources to achieve higher rates of product supply is not a new service performed by G.James. We are capable of performing this kind of logisitical coordination to make this scale of projects feasible. G.James welcomes discussion to assess how we can provide solutions for any similar large projects.

A project showcasing the many products G.James Glass & Aluminium and affiliates produce, is due to open next week. Facets of the G.James organisation, including metal fabrication,

A project showcasing the many products G.James Glass & Aluminium and affiliates produce, is due to open next week. Facets of the G.James organisation, including metal fabrication,

Ongoing development of a historical site located at Newstead (Brisbane), sees it transforming in stages to a new mixed use precinct. The name derives from the sites original use – the gasworks, and part of the project is to protect the heritage listed gasometer located prominently amid the gasworks buildings.

Ongoing development of a historical site located at Newstead (Brisbane), sees it transforming in stages to a new mixed use precinct. The name derives from the sites original use – the gasworks, and part of the project is to protect the heritage listed gasometer located prominently amid the gasworks buildings.

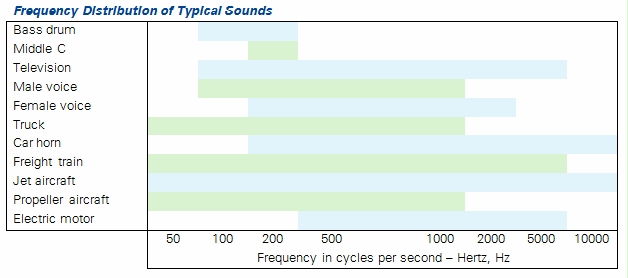

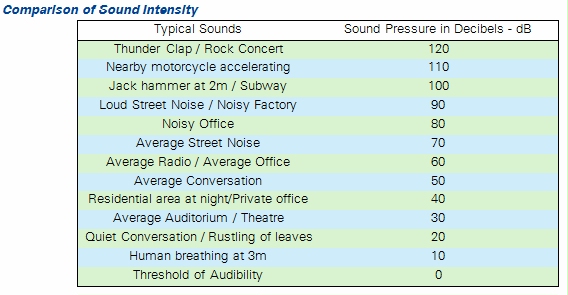

Insulating Glass Units (IGUs) or double glazing, have been a popular solution to control noise, but they aren’t the only, or even the best solution in many cases. The aim of this article is to explain how acoustic problems are identified, assessed and provide solutions to properly address them.

Insulating Glass Units (IGUs) or double glazing, have been a popular solution to control noise, but they aren’t the only, or even the best solution in many cases. The aim of this article is to explain how acoustic problems are identified, assessed and provide solutions to properly address them.

The G.James Glass and Aluminium Plastics department has been operating since 1995, and started out manufacturing just 2 products for in house use. Type and quantity of manufacturing has been growing steadily ever since. Commercial sale of products initiated 5 years ago, and now supports several industries.

The G.James Glass and Aluminium Plastics department has been operating since 1995, and started out manufacturing just 2 products for in house use. Type and quantity of manufacturing has been growing steadily ever since. Commercial sale of products initiated 5 years ago, and now supports several industries.

A green star accredited office block constructed in one of Brisbane’s growing commercial areas, 51 Alfred St comprises of a ground floor retail space with 8 levels of office space above.

A green star accredited office block constructed in one of Brisbane’s growing commercial areas, 51 Alfred St comprises of a ground floor retail space with 8 levels of office space above.

G.James’ work on the project comprised the design, supply and installation of windows, doors, curtain walls, glass walls, glass canopies, a glass greenhouse, aluminium cappings and soffits– utilising our 850-500, 651, 451, 475 and 476 Series frames. Jockey sashes from our 150 Series were required for most windows, and some windows also featured curved heads. G.James’

G.James’ work on the project comprised the design, supply and installation of windows, doors, curtain walls, glass walls, glass canopies, a glass greenhouse, aluminium cappings and soffits– utilising our 850-500, 651, 451, 475 and 476 Series frames. Jockey sashes from our 150 Series were required for most windows, and some windows also featured curved heads. G.James’  Four “curtain wall” sections were defined by the Architect and included in G.James’ scope of work. Two of these were fabricated as 850-500 Series structural glazed curtain walls. The Stair glazing used the 850-500 Series structural glazed frame as a window wall fitted between steel horizontal supports. Coloured back glass was used to infill between the frames and hide the steel. Jockey sashes and secondary frames were used behind these frames to create large cavities for acoustics. On one curtain wall an additional 850 Series frame was used as an internal frame to provide the nominated 400mm airspace.

Four “curtain wall” sections were defined by the Architect and included in G.James’ scope of work. Two of these were fabricated as 850-500 Series structural glazed curtain walls. The Stair glazing used the 850-500 Series structural glazed frame as a window wall fitted between steel horizontal supports. Coloured back glass was used to infill between the frames and hide the steel. Jockey sashes and secondary frames were used behind these frames to create large cavities for acoustics. On one curtain wall an additional 850 Series frame was used as an internal frame to provide the nominated 400mm airspace.