Introduction

Thermal stress occurs in glass when there is a temperature variance in different parts of the glass. If the stress caused by the temperature difference is greater than the strength of the glass, thermal stress glass breakage will result.

Thermal stress glass breakage is not a new phenomenon and it has been relatively well understood in commercial glazing for many years. However, given the increasing use of high performance, energy efficient glazing and the fact that some of these products can carry a greater risk of thermal stress, it is important that everyone involved in the glazing industry has a better understanding of thermal stress, its cause and how to prevent it.

As thermal stress breakage is not often due to a glass fault, but rather the result of a set of conditions that a pane of glass is exposed to, it is generally not covered by a glass supplier’s warranty.

Identifying thermal stress glass breakage

A glass fracture can be identified as a thermal stress breakage if the start of the crack is at 900 to both the edge of the glass AND the face of the glass. Depending on the magnitude of the stresses involved, the crack may only travel for a few millimetres before branching out or veering off-line, so the 90° angle of the initial fracture may not always be immediately apparent.

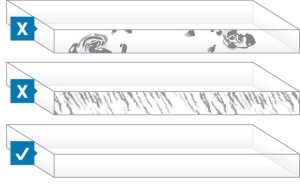

Breakages caused by thermal stress can be characterised as either low stress breakages or high stress breakages. Low stress breakage is characterised by a single crack that “lazily” makes its way across the glass, while high stress breakage is identifiable by the initial crack branching off into a number of separate fissures a short distance from its origin.

What causes thermal stress?

As mentioned previously, thermal stress is caused by varying temperatures in different parts of a glass pane. Absorption of the sun’s energy is one of the main causes of this temperature difference. The section of glass exposed to the sun absorbs the sun’s energy and, as a result, heats up. Any part of the glass which is shaded from the sun, for example, by the window frame, stays relatively cool.

The hot glass expands while the smaller, cooler area doesn’t. If the cool area of the glass isn’t strong enough to withstand the forces imposed by the expanding hot section of the glass, thermal stress breakage will occur. Putting the forces required to induce thermal stress into perspective, Pilkington estimate that for every degree in temperature difference between the edge of the glass and the centre of the glass, around 0.62 MPa of stress is introduced into the glass. Given that in some cases temperature differences of 20 to 30°C can occur, that equates to around 12 to 19 MPa. This is higher than the design stress used for wind loading!

Thermal stress risk factors

Given that thermal stress is caused by differences in temperature in a piece of glass and that breakage occurs when the ability of the glass to withstand this stress is exceeded, any situation or factor that increases this temperature difference, or decreases the glass’s strength, increases the risk of the thermal stress breakage.

Factors that can affect the risk of thermal stress include:

Edge Condition

Damage to glass edges during manufacture or installation is arguably the largest cause of low stress thermal breakage.

As US glass manufacturer PPG puts it: “The as-cut quality of glass edges is the single most important factor affecting the edge strength of glass. Poor cut-edges quality can reduce the glass strength by 50% or more…” “Glass edge quality and the resulting glass edge strength is particularly critical to the performance of the glass under the thermal loading …”  The level of thermal stress that a piece of glass can withstand is directly affected by the condition of the glass edges. The edges that are most resistant to thermal stress breakage are good quality clean-cut edges with no shells, vents or shark teeth. This may be difficult to achieve in laminated glass and edgework may be required to smooth the edges.

The level of thermal stress that a piece of glass can withstand is directly affected by the condition of the glass edges. The edges that are most resistant to thermal stress breakage are good quality clean-cut edges with no shells, vents or shark teeth. This may be difficult to achieve in laminated glass and edgework may be required to smooth the edges.

Glass Type

Different glass products have a different tolerance to thermal stress. Generally, the more solar energy a glass product absorbs, the higher the risk of thermal stress breakage. All glass manufacturers provide data on the solar energy absorption properties for their products.

Solar absorption can vary greatly, even between similar products. The use of a reflective coating can significantly increase the amount of solar absorption. This is because, in effect, the glass is absorbing the solar energy both on the way into the glass and then again on the way out after it hits the reflective coating.

Example:

Uncoated 6mm grey glass has a solar absorption rate of around 45%, while the addition of a reflective coating to this product increases solar absorption to 63%.

The use of transparent Low E coatings can also increase the solar absorption rate of glass. Low E coatings are designed to reduce the passage of radiant heat flow through the glass to improve energy efficiency. This leads to higher glass temperatures and increases the risk of thermal stress.

Another significant risk factor is the addition of heat absorbing films or any partial covering of a glass pane by other products (such as signs or paint) after installation. Both of these can increase the risk of thermal stress.

Glass Size

The larger a pane of glass, the greater the area of glass that is absorbing the sun’s energy, compared to its relatively narrow cooler edges. The larger area of hot glass results in higher levels of thermal stress in the edges of the glass.

Exterior Shading

Whilst glass properties are well documented and can be taken into account during the design phase of a project, accounting for exterior shading can be more problematic.

The effect that an external shading device has on thermal stress depends on a combination of its size, shape and location on the glass. Exterior shading is further complicated by its seasonal nature; as the sun’s position changes throughout the year so too does the shadows it casts.

In general:

- Shading that covers 50% or less of the glass is more unfavourable than a device that shades a greater percentage of the glass;

- Static shading is more unfavourable than mobile shading;

- V or L shaped shading induces higher thermal stress, particularly if the point of the V falls on an edge of the glass.

Interior Shading

A thermal stress risk factor that is encountered more often in residential construction than commercial, is the use of curtains and blinds on the inside of a window. The impact that blinds and curtains have on thermal stress depends on the colour, type and other factors, however the effect can be significant.

While close fitting blinds or curtains help to minimise heat transmission into or out of the building, they can significantly add to the risk of thermal stress. To minimise this, the space between the glass and shade must be at least 50mm (preferably 150mm) and should be vented. Ventilation is provided by leaving a gap between the blinds and the walls, or frame, of 50mm at the head and 25mm at the sill.

The effect that blinds and curtains have on thermal stress is also dependent upon how much energy they reflect back onto the glass. Light colours are good reflectors while dark colours are not. Closed weave fabric helps trap heat more effectively while open weave lets the heat pass through. Venetian blinds are excellent heat reflectors as are metallised blinds.

Heating & Cooling

Artificial heating and/or cooling devices should be positioned so that they do not blow hot or cool air directly onto the glass surface, nor into the space between the glass and the curtains. Doing so may result in varying temperatures on the glass surface and therefore increase the risk of thermal stress.

Glazing Method

Commonly used glazing methods do not significantly affect the risk of thermal stress. The exception to this is structural glazing, which reduces the levels of thermal stress by reducing the temperature difference between the glazed edge and the centre of the glass. Care should be taken when using any glazing method that either encourages the transfer of heat away from the glass or covers unusually large amounts of the edges of the glass.

Managing the risk of thermal stress

The risk of thermal stress breakage can be eliminated by managing the factors outlined above or by heat strengthening the glass.

Heat strengthening increases the strength of the glass, which allows it to resist the thermally induced stress. Heat strengthening can be relatively expensive, particularly if required for laminated glass, so unless replacing glass, which has been broken under thermal, stress, a method of quantifying the risk level is needed.

Many glass manufacturers’ websites provide detailed information on thermal stress breakage. Some also provide online tools that enable you to perform a thermal stress analysis yourself, or they will perform a thermal stress analysis for you providing you purchase glass from them.

By using available information, the glass installer can objectively assess the risks prior to installation. In some cases redesign may be possible, eliminating the need for heat strengthening and therefore saving unnecessary expense.