G.James Glass & Aluminium has recently enhanced its ColourLite ceramic printed glass range and capability with investment in the next generation ceramic on-glass printing technology. This process is renowned internationally as one of the world’s leading digital on-glass printing systems.

G.James Glass & Aluminium has recently enhanced its ColourLite ceramic printed glass range and capability with investment in the next generation ceramic on-glass printing technology. This process is renowned internationally as one of the world’s leading digital on-glass printing systems.

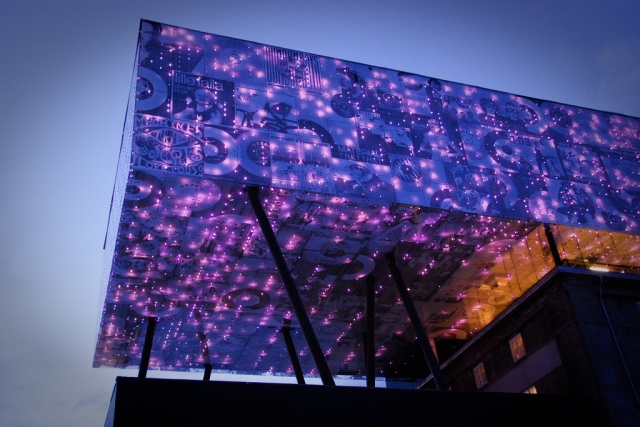

Australian architects and designers now have access to a new world of high-definition, full colour glass printing capabilities, including photo-realistic images that will redefine the role of printed glass as a design showpiece for façades, feature walls, interior fit outs, signage and other architectural highlights.

On-glass digital ceramic printing differs from other printed glass technologies in its vivid richness, hardiness and imaging flexibility. The digital ceramic inks are made from microscopic glass particles and inorganic pigments that are fused to the surface of glass through the glass furnacing process. The result is an extremely durable product that is highly resistant to fading. ColourLite ceramic printed glass is a truly robust imaging system with the capacity to handle the most expressive, forceful design ideas.

Lewis Saragossi, Managing Director and Chairman of G.James, says as a local manufacturer, he and his team are delighted to introduce new ColourLite capabilities to Australian architects and designers.

“We are very excited to add this new technology to our extensive product line and offerings,” he says. “We have spent a great deal of time evaluating the various technology options to find the one that would best match the needs and demands of the Australian market as well as current and future design trends. Our customers are impressed with the short lead time, available from our three local manufacturing facilities in Melbourne, Sydney and Brisbane.”

This new imaging software allows designers to accurately portray single images over multiple glass panels, and there is flexibility to present different designs. For example, the printing system allows for a continuous design to cover the full extent of a building façade for maximum impact. This includes the possible use of full perforated imaging to the vision panels. The unique digital system caters for either individual or multiple panel printing without the excessive cost and limitations of a silk screen.

Whats New?

- High definition 720dpi printing

- Glass thickness from 4mm to 19mm

- Automatic inline pre mix colour range

- Sizes from 300 x200mm to 4000 x 2300mm

1. Cardboard Cathedral Christchurch New Zealand Image supplied by Dip-Tech Photography by Bridgit Anderson 2. Fletcher Hotel Amsterdam, Holland Image supplied by Dip-Tech 3. G.James Glass & Aluminium Cairns, Australia Photography by Mark McCormack